THE NEW COLUMBUS

THE TEAM

The passionate individuals that stand behind Columbus

THE NEW COLUMBUS

UX DESIGN

The passionate individuals that stand behind Columbus

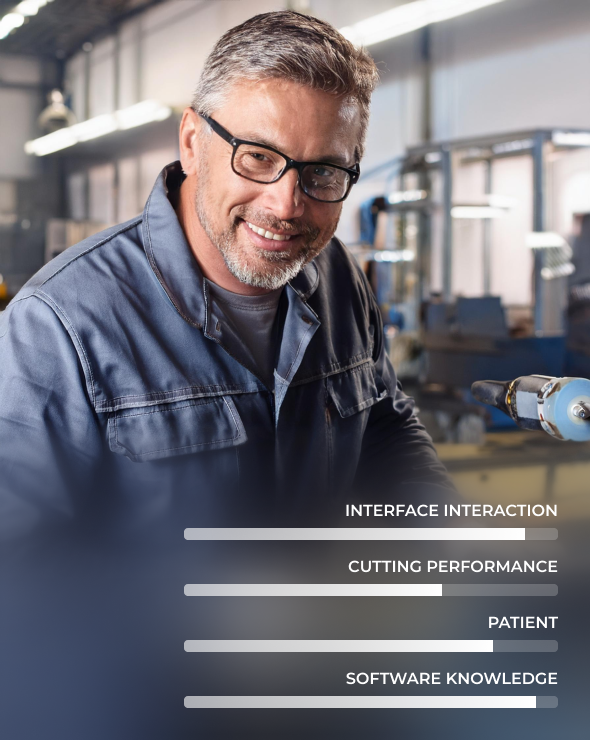

Teamleader Development Engineer & Product Manager Application

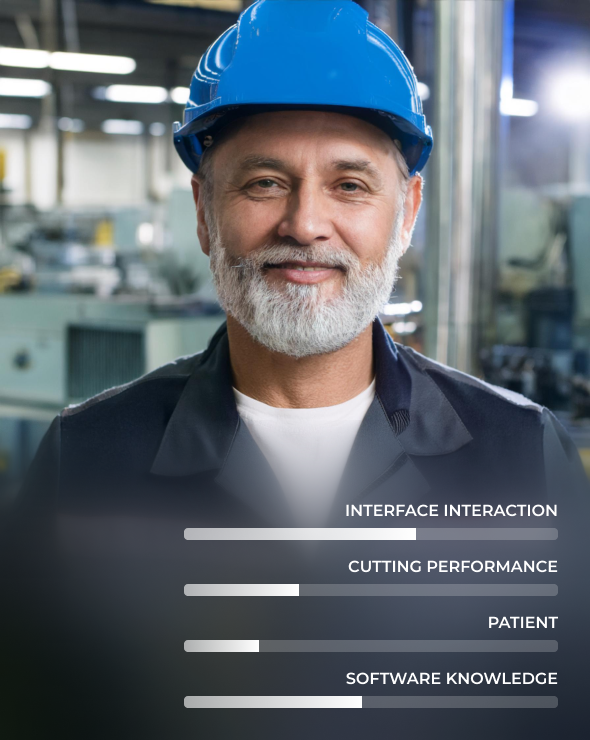

Software Engineer Columbus

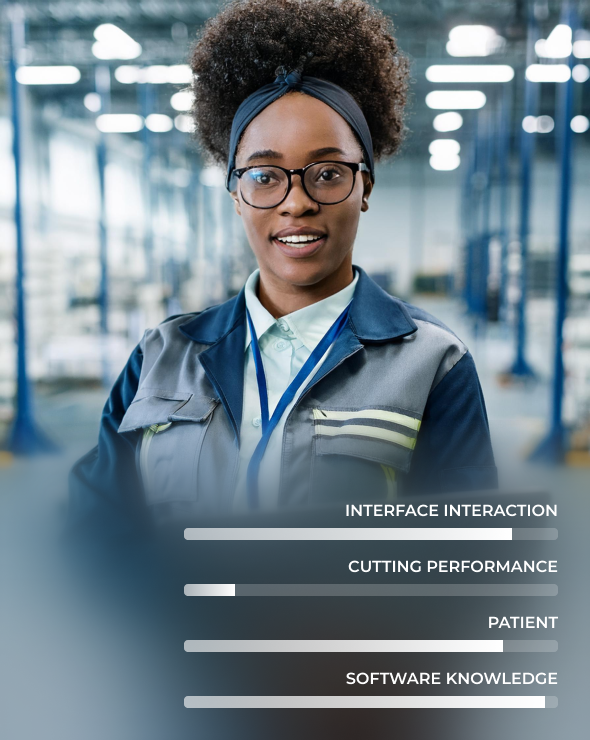

Project Engineer Application Software

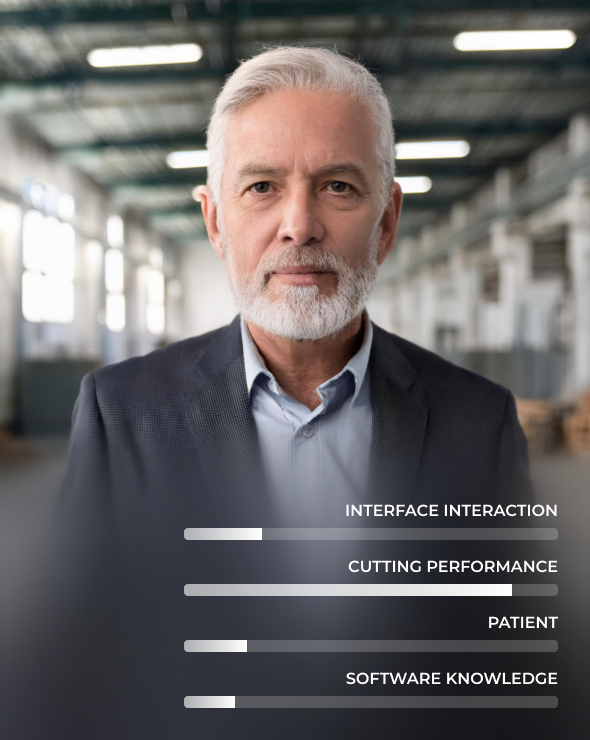

Trainer Columbus

Development Engineer Application

Columbus Hotline & Software testing

Senior UI/UX designer

Senior UI/UX designer

Work preparation dept.

40 y.o. | Married | Work size: 100 | 3 years after school education | Family sedan

BIO

Adam spent most of his career next to computers and cutting/cnc machines. Aside from this, he has good knowledge of materials, consumables and other industry related things. His wealth of knowledge makes him the perfect mentor and he helps support with the tough questions.

WORK RESPONSIBILITIES

Work preparation dept. but different areas

50 y.o. | Diverced | Work size: 100 | 3 years after school education | Harley Davidson

BIO

Tobias is more hands on and likes to work with his hands. He grew up from the shop floor and has a well rounded understanding of all aspects of production. Even though he has been exposed to software in his career, his interest lie else where. When he comes home, he rather work on his bike.

WORK RESPONSIBILITIES

Works with everything computer related

26 y.o. | Single | Work size: 20 | 3 years vocational training | Electric bike

BIO

Maria loves computers and everything related to them. Although she has limited knowledge of the cutting industry, she understand software and how to get around should there be a problem. A valuable team player and a fast learner. Passionate about electric scooters and electric bikes. Vegan.

WORK RESPONSIBILITIES

Business owner

55 y.o. | Married | Work size: 7 | Self-made | SUV (Sports Utility Vehicle)

BIO

Robert is a stressed business owner where the ultimate responsibility falls on him. Therefore, he is a jack-of-all-trades and has limited exposure to software. But sometimes he needs to dive deeper and solve problems so he needs a simple and intuitive solution.

WORK RESPONSIBILITIES

UI DESIGN

FUTURE FEATURES

TECHNOLOGY / AI

We want to offer a 3rd storage location - the cloud.

The users should be able to upload nests, parts, settings and have them available anywhere they go.

They can also easily share their assets and settings with other team members.

Ideally, they can use any of the big cloud services aside from InduSuite Cloud.

Save everything in the cloud and automatically connect with provisioned machines

Connect to your company server and ERP system

Create a local server on your computer. This will install a local database on your computer

In today’s manufacturing landscape, integrating advanced technologies is essential for optimizing workflows and boosting productivity. Our digital products streamline operations from design to production phase.

Columbus CAD/CAM enables users to create NC programs and plan cutting operations with an intuitive UI.

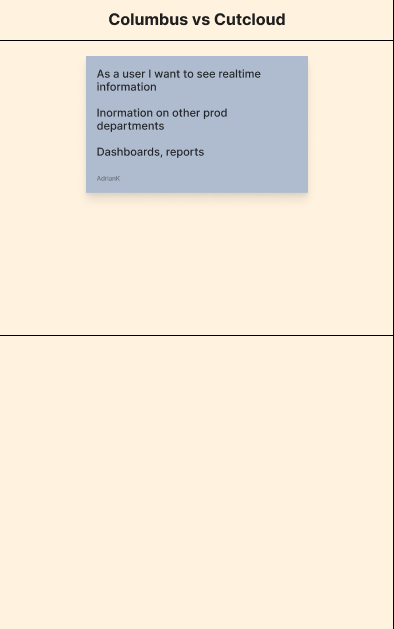

CutCloud provides real-time data and analytics for effective cutting process management.

WeldCloud Assembly integrate seamlessly with Columbus and CutCloud, allowing real-time tracking and QA while enabling high weld standards and traceability.

FloCloud offers easy data management and analytics for gas consumption, even providing carbon footprint of produced parts.

This powerful ecosystem enhances collaboration, increases efficiency, and drives innovation in manufacturing, enabling businesses to be more agile and responsive in a dynamic market.

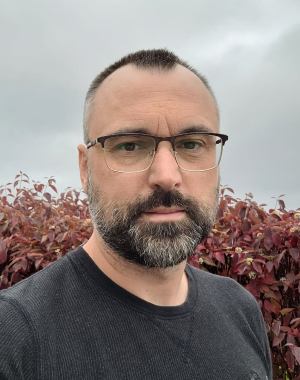

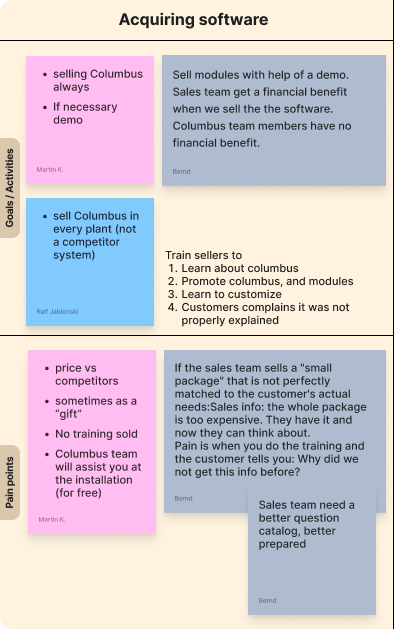

BUSINESS

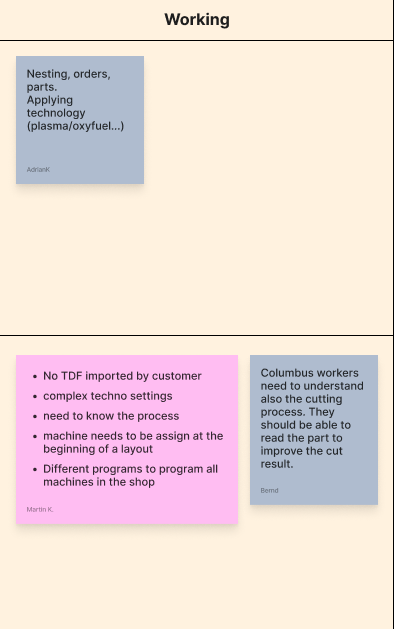

The people in this department are constantly looking for opportunities to increase productivity while maintaining a high-quality output. Columbus enables them to be fast in creating programs for cutting machines and getting the best quality possible at the same time for ESAB machines.

In their position, traceability is paramount, and there´ll come a time that they´ll need to troubleshoot why part quality is not as expected. Columbus assists the user to have the best quality possible by automating technology settings. It also provides all the data necessary to trace a part back to machine and material used to identify the problem and prevent future issues.

Business Owners strive to increase profits and set-up their organization for future growth. Columbus allows the operation to maximize resource utilization by using material more efficiently and allowing employees to work more quickly.

Their main focus is productivity by optimizing the workflow in the workshop. Columbus uses the maximum possible productivity by maintaining highest quality output on the machines. ESAB machines are also directly connected to Columbus to avoid unnecessary work by manually reporting the outcome of a NC program.

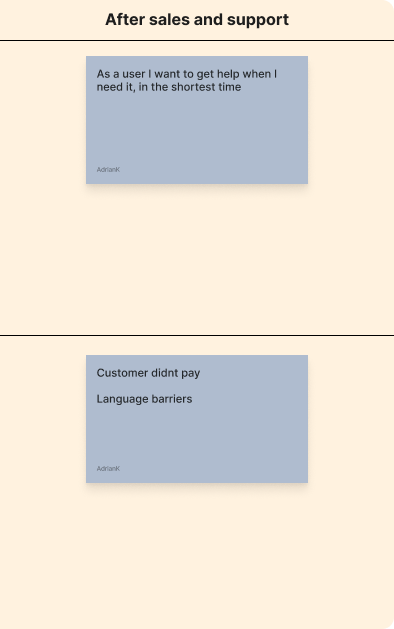

Make every programmer and operator a pro with minimal learning curve thanks to the built-in logic new intuitive and easy-to-use UI.

Minimize the material waste from your cutting operations by automatically optimizing nesting across multiple plates by using AI powered algorithms .

Program complex multi-pass bevel parts in half the time by automatically generating bevel commands using the new intuitive and easy-to-use UI .

Schedule the cutting work and events like preventive maintenance and planned down time for your fleet of cutting machines. The new Projects feature gives a greater progress overview, the possibility to create groups and group work items for a more efficient monitoring process.

Save up to 50% in production lead time and maximize data quality by avoiding manual data transport and handling. Improve cut quality by a fully predictable and repeatable process. Streamline the production process by using the power apps as add-ons, connect to ERP and other systems through standard API, use common interfaces, power automate .

In our ongoing efforts to enhance our offerings, we will develop brand-agnostic post-processors in addition to ESAB machines. This initiative is, based on the reachable global market, generating approx. $4 million in recurring revenue after 5 years.

We are also introducing cloud storage as a new revenue stream. This implementation is projected to yield around $100,000 for every 100 users, providing a significant boost to our financial performance and makes excellent customer support affordable.

Our Columbus platform will transition to a subscription-based model. New accounts will be required to subscribe, while existing accounts will have the option for a reduced subscription that includes maintenance and support. By converting 50% of our user base to this subscription model, we anticipate generating about $1 million in yearly recurring revenue.

Monthly

Monthly

Monthly

Monthly